Mastering Cold Chain Logistics: Maintaining Integrity During Summer Border Crossings

Cold chain logistics play an essential role in global supply chains, allowing temperature-sensitive products to maintain their safety, efficacy, and shelf life from origin to destination. This specialized logistics system involves the transportation and storage of goods within controlled temperature ranges.

Cold Chain Logistics Explained

Cold chain logistics is a specialized part of supply chain management that focuses on transporting and storing temperature-sensitive products under carefully controlled conditions to maintain their quality and safety.

This system is essential for products that must stay within specific temperature ranges, usually between 2°C and 8°C (About 35-46°F), to remain effective or safe. These include:

- Pharmaceuticals like vaccines, insulin, and biologics

- Perishable foods such as dairy, meat, seafood, and fresh produce

- Specialty chemicals and lab materials sensitive to temperature fluctuations

Cold chain logistics involves a coordinated network of refrigerated transportation (known as reefer trucks), cold storage warehouses, insulated packaging, and advanced temperature monitoring systems. Each step in the chain, from manufacturing to final delivery, must provide consistent cooling to prevent spoilage.

It requires a seamless, end-to-end process involving refrigerated vehicles, insulated packaging, real-time temperature monitoring, and strict handling protocols to avoid exposure to damaging environmental conditions.

Key Risks of Summer Border Crossings

The importance of cold chain logistics becomes even more pronounced during the summer months, when extreme heat poses a threat to cargo integrity, especially at high-traffic international crossings like the Tijuana-San Diego border. Maintaining cold chain integrity during summer border crossings is an essential safeguard for consumer safety, maintaining regulatory compliance, and protecting the financial investment in temperature-sensitive goods.

Top Risks to Cold Chain Shipments in Summer:

The following underscores the top risks that threaten temperature-sensitive shipments during cross-border transport, each of which can disrupt the cold chain and lead to significant product loss.

- Temperature Excursions

Idle trucks in long border queues often face intense heat, which strains refrigeration units and can cause cargo temperatures to exceed safe limits (usually 2°C to 8°C). - Unpredictable Border Delays

Summer vacation traffic and stricter inspections cause longer wait times. Some commercial vehicles experience delays exceeding four hours, endangering temperature-sensitive goods. - Multiple Handling Points

Each time cargo is moved. from truck to customs to warehouse, the risk of losing temperature control increases. - Regulatory Complexity

Differing cross-border standards and documentation requirements can stall clearance, leaving products vulnerable to temperature fluctuations.

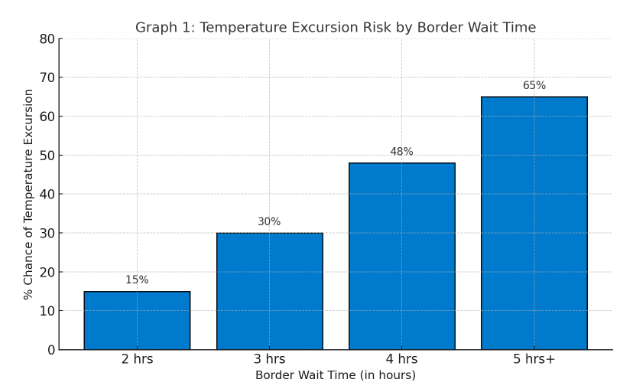

Temperature Excursion Risk by Border Wait Time

This graph visualizes how wait times at the border increase the risk of temperature deviations in cold chain logistics.

After just 3 hours of wait time, nearly one-third of shipments face temperature breaches, posing a serious threat to the safety and viability of sensitive goods.

Best Practices for Maintaining Cold Chain Integrity

The best way to combat heat and delays is to proactively implement a multi-layered defense system across technology, packaging, and planning.

Cold Chain Best Practices:

- Real-Time Temperature Monitoring

Equip shipments with IoT-enabled sensors that alert teams when temperatures drift. These systems offer live tracking, essential for in-transit visibility. - Use Advanced Insulated Packaging

Implement phase-change materials, vacuum-insulated panels, and pre-cooled containers to buffer external heat exposure during delays. - Schedule Crossings Strategically

Plan border crossings during early morning or nighttime to avoid the worst heat and traffic congestion. - Partner with C-TPAT Certified Carriers

These carriers streamline customs inspections and reduce wait times, especially useful in summer when delays are common. - Establish Emergency Protocols

Set protocols for rerouting, re-cooling, or offloading products if conditions breach acceptable limits.

Comparison of Cooling Techniques for Border Crossings

Choosing the right cooling method is essential for preserving cold chain integrity during summer border crossings, where heat exposure and delays can compromise even well-managed shipments. The following table compares common cooling techniques based on their effectiveness in hot conditions and overall cost efficiency.

| Cooling Method | Description | Summer Suitability | Cost Efficiency |

| Passive Cooling | Gel packs, dry ice, insulated boxes | Moderate | High |

| Active Cooling | Reefer trucks with mechanical systems | Excellent | Moderate |

| Hybrid Cooling | Passive + active systems | Excellent | Moderate |

| Pre-Cooling and Staging | Cooling at origin before loading | Good | High |

| Phase-Change Materials | Custom temp-maintaining substances | Very High | Moderate |

Hybrid cooling and phase-change materials provide superior performance in extreme heat while maintaining cost efficiency for high-value shipments.

Technology That Safeguards Cold Chain Logistics

Modern logistics providers are embracing digital tools to keep products cool and compliant at the border, even in the heat of summer.

Cold Chain Technology Innovations:

- IoT-Based Sensors

Provide minute-by-minute updates on cargo temperature and humidity, alerting drivers to anomalies. - AI Route Optimization

AI systems reroute deliveries based on weather forecasts, traffic conditions, and customs clearance times to minimize delay-related exposure. - Blockchain for Secure Documentation

Digitizes and secures paperwork for faster customs clearance and complete transparency across stakeholders. - Remote Intervention Tools

Allow logistics managers to adjust reefer unit settings in real time, based on sensor data.

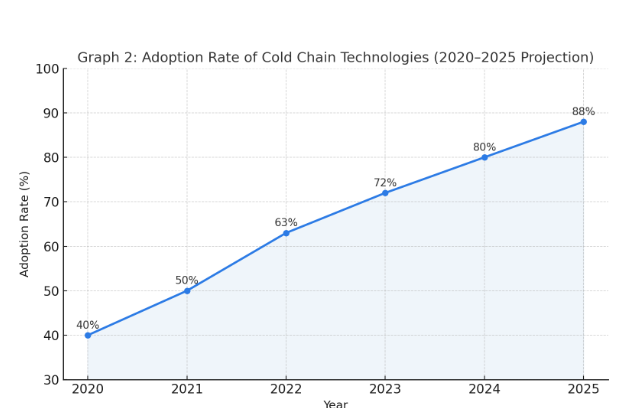

Adoption Rate of Cold Chain Technologies (2020–2025 Projection)

This adoption curve is based on expert-modeled estimates of IoT and related digital system integration in logistics, illustrating how rapidly industry leaders are integrating digital systems, such as IoT sensors, AI-based monitoring, and blockchain, into their cold chain operations. It forecasts increasing deployment from 40% in 2020 to nearly 90% by 2025.

The industry is rapidly moving toward near-universal adoption of real-time and AI-based systems to combat challenges posed by summer border conditions.

Future Outlook and Sustainability Trends

As global temperatures rise and international trade expands, logistics providers are investing in long-term solutions to safeguard the cold chain. These include:

Emerging Trends in Cold Chain Logistics:

- Climate-Resilient Refrigeration

New energy-efficient systems powered by solar or alternative fuels maintain cooling in grid-disrupted or extreme-heat environments. - Green Cold Chain Practices

From biodegradable insulation to electric reefer units, sustainability is becoming integral to cold chain strategy. - Data-Driven Compliance Management

Enhanced analytics tools now forecast regulatory hurdles and auto-generate required documentation for faster border movement. - Training and Certification Programs

More logistics companies are investing in staff education to ensure best practices are maintained throughout the supply chain.

Regulatory Checklist for Summer Border Cold Chain Compliance

To ensure cold chain integrity during summer border crossings, shippers must meet strict regulatory requirements that govern both temperature control and documentation. Neglecting just one compliance step can lead to customs holds or spoilage penalties. Key compliance elements that help minimize delays, ensure safety, and prevent costly spoilage or legal issues are tabled below:

| Requirement | Description | Applies To |

| C-TPAT Certification | Streamlined customs process for trusted partners | U.S. Cross-Border Shipments |

| Temperature Monitoring Logs | Continuous digital records of shipment temps | All Cold Chain Goods |

| Bilingual Documentation | Spanish/English customs paperwork | U.S.-Mexico Border |

| Labeling Compliance | Temp range and handling instructions | Perishables & Pharma |

| Reefer Maintenance Records | Proof of unit inspection and functionality | Reefer Truck Shipments |

Safeguard Your Cold Chain with Reliable Solutions

Maintaining cold chain integrity during summer border crossings is a strategic necessity. From advanced monitoring systems to smarter route planning, the industry is evolving rapidly to combat rising temperatures and longer wait times.

Mex-Cal Truckline brings over 40 years of experience to this space, offering:

- State-of-the-art refrigerated transport

- 24/7 real-time tracking and intervention

- Seamless cross-border compliance solutions

Don’t let summer heat compromise your cargo. Partner with Mex-Cal for reliable cold chain logistics tailored for high-risk border conditions. Contact us now and secure your temperature-sensitive cargo with confidence.